How Does a Film Scanner Work? – Anatomy of a Scanner

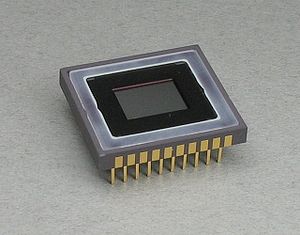

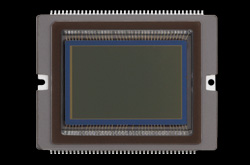

Parts of a typical negative-slide scanner include: * Charge-coupled device (CCD) or CMOS array * Mirrors * Scan head * Lamp * Lens * Stepper motor (Only on motorized scanners) * Power supply * Interface port(s) * Control circuitry. These are housed in a variety of cases.

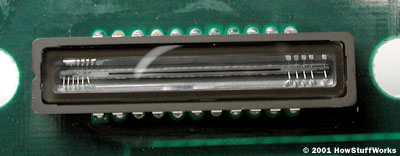

The core component of the scanner is the CCD array which is the most common technology for image capture in scanners. CCD is a collection of light-sensitive diodes, which  convert light into electrons. These diodes are called photosites. The brighter the light that hits a single photosite, the greater the electrical charge that will accumulate at that site. CCD (charge-coupled device) and CMOS (complimentary metal-oxide semiconductor) image sensors convert light into electrons.The values of these electrons (accumulated charge) is read for each cell in the image. In a CCD device, the charge is transported across the chip and read at one corner of the array while in most CMOS devices, there are severa

convert light into electrons. These diodes are called photosites. The brighter the light that hits a single photosite, the greater the electrical charge that will accumulate at that site. CCD (charge-coupled device) and CMOS (complimentary metal-oxide semiconductor) image sensors convert light into electrons.The values of these electrons (accumulated charge) is read for each cell in the image. In a CCD device, the charge is transported across the chip and read at one corner of the array while in most CMOS devices, there are severa l transistors at each pixel that amplify and move the charge using more traditional wires. This approach is more flexible because each pixel can be read individually. Because of manufacturing differences, there have been some noticeable differences between CCD and CMOS sensors.CCD sensors create high-quality, low-noise images whereas CMOS sensors, traditionally, are more susceptible

l transistors at each pixel that amplify and move the charge using more traditional wires. This approach is more flexible because each pixel can be read individually. Because of manufacturing differences, there have been some noticeable differences between CCD and CMOS sensors.CCD sensors create high-quality, low-noise images whereas CMOS sensors, traditionally, are more susceptible to noise.

to noise.

The Scanning Process

Here are some steps that a scanner goes through when it scans a negative or slide.

Step 1: The scanner identifies the type of film. Some film scanners have databases of films so that all you need to do is select what type of film you are using while others look for the lightest or least dense part of the frame and sets the scanner to scan the frame or strip using this setting – on some brands and models this is seen as measuring the minimum density of the film.

Step 2: The Negatives are Illuminated. The scanner uses an LED, or Cold Cathode Lamp to light up the negatives. Two or three mirrors then reflect the image through different filters and lenses until it reaches the CCD (C harged Coupled Device). Some scanners, such as Canon’s Canoscan, use infrared light so the connecting software can easily identify and remove dust before the negative is scanned onto the computer.

harged Coupled Device). Some scanners, such as Canon’s Canoscan, use infrared light so the connecting software can easily identify and remove dust before the negative is scanned onto the computer.

Step 3: The Information is Collected: The image of the frame that you scan reaches the CCD array through a series of mirrors, filters and lenses. The exact configuration of these components will depend on the model of scanner, but the basics are pretty much the same.

Step 4: An analog-to-digital converter turns each pixel’s value into a digital value. The resulting scan is either a simple raw image ready to be edited, or it can be a compressed image that the scanning software has enhanced.

Resolution and Interpolation

Scanners vary in resolution and sharpness. Most 35mm negative scanners have a true hardware resolution of at least 1800 dots per inch (dpi). The scanner’s dpi is determined by the number of sensors in a single row (x-direction sampling rate) of the CCD and/or by the precision of the stepper motor if available (y-direction sampling rate). Sharpness depends mainly on the quality of the optics used to make the lens and the brightness of the light source. A bright lamp and high-quality lens will create a much clearer, and therefore sharper, image than a standard lamp and lens.

Interpolation is a process that the scanning software uses to increase the perceived resolution of an image. It does this by creating extra pixels in between the ones actually scanned by the input array. These extra pixels are an average of the adjacent pixels. For example, if the hardware resolution is 300×300 and the interpolated resolution is 600×300, then the software is adding a pixel between every one scanned by a CCD sensor in each row. Another term used when talking about scanners is bit depth, also called color depth. This simply refers to the number of colors that the scanner is capable of reproducing. Each pixel requires 24 bits to create standard true color. Many of them offer higher bit depths but they still only output in 24-bit color and perform internal processing to select the best possible choice out of the colors available in the increased palette. There are many opinions about whether there is a noticeable difference in quality between 24-, 30- and 36-bit scanners.

Interpolation is a process that the scanning software uses to increase the perceived resolution of an image. It does this by creating extra pixels in between the ones actually scanned by the input array. These extra pixels are an average of the adjacent pixels. For example, if the hardware resolution is 300×300 and the interpolated resolution is 600×300, then the software is adding a pixel between every one scanned by a CCD sensor in each row. Another term used when talking about scanners is bit depth, also called color depth. This simply refers to the number of colors that the scanner is capable of reproducing. Each pixel requires 24 bits to create standard true color. Many of them offer higher bit depths but they still only output in 24-bit color and perform internal processing to select the best possible choice out of the colors available in the increased palette. There are many opinions about whether there is a noticeable difference in quality between 24-, 30- and 36-bit scanners.